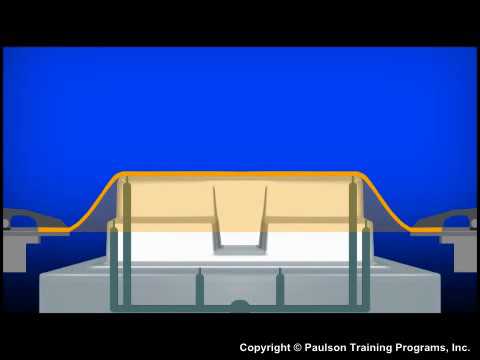

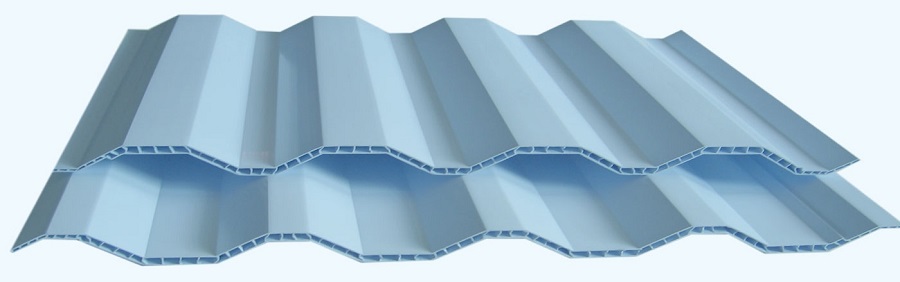

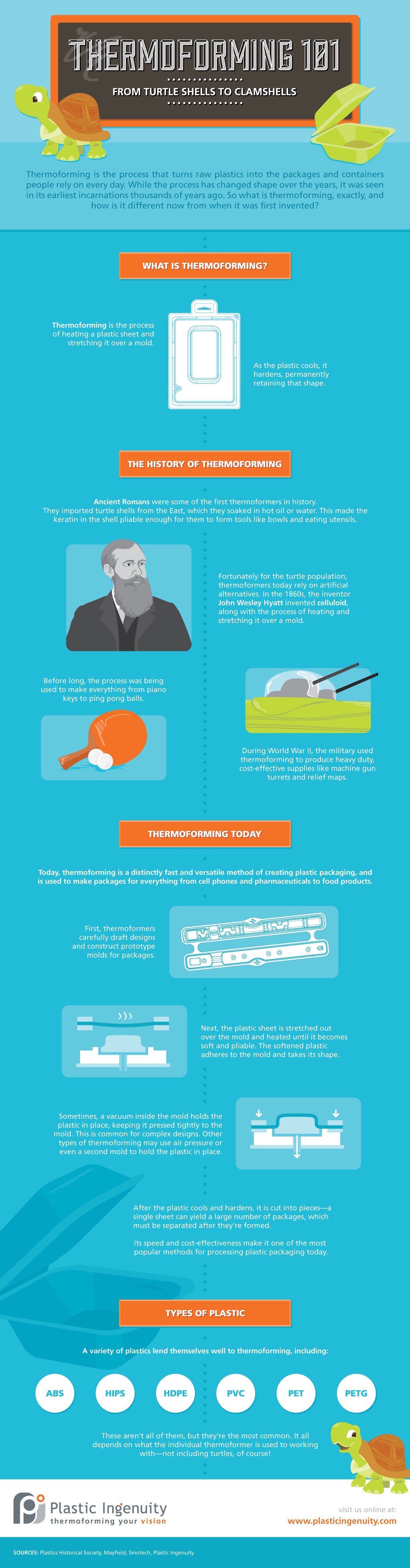

Thermoforming is the process of heating a plastic material in sheet form to its particular processing temperature and forming the hot and flexible material against the contours of a mold by mechanical means e g tools plugs solid molds etc or pneumatic means e g differentials in air pressure created by pulling a vacuum or using the pressures of compressed air.

Most flexible plastic sheet thermoforming.

Some plastics like hdpe and pp have narrower processing windows and lower melt strength which make them more difficult but not impossible to thermoform.

A phenomenon that occurs when the area of the melted sheet is larger than the mold s ability to capture it.

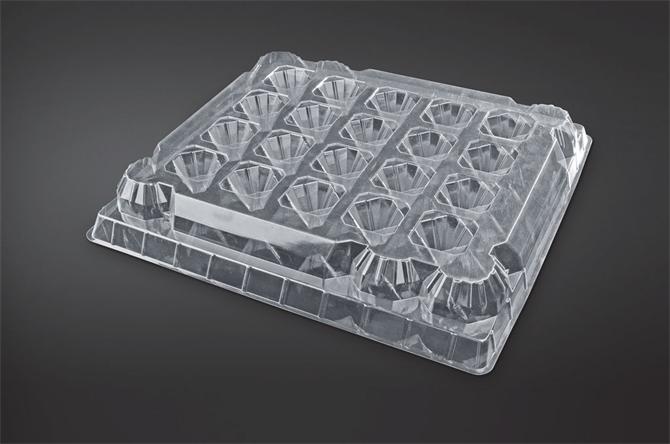

In a thermoforming process a plastic sheet is warmed and formed into a cavity.

Get it as soon as thu sep 10.

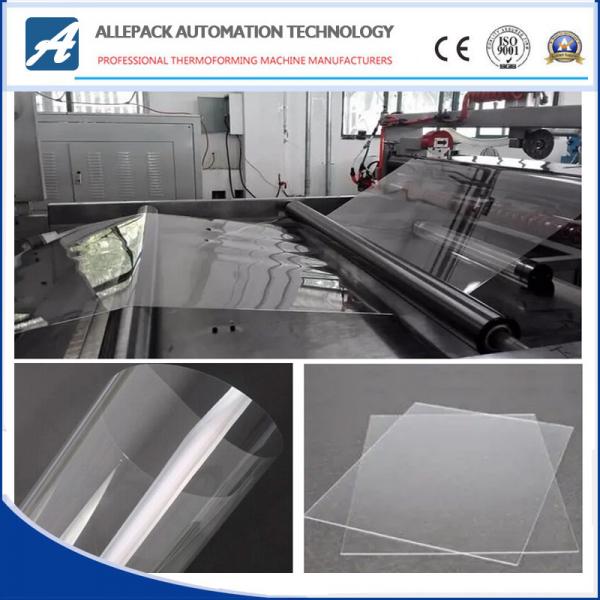

Many plastic sheet materials can be shaped by thermoforming.

The basic vacuum forming process is the foundation on which more flexible and elaborate thermoforming processes are built by adding elements such as billow and plug pre stretching of the sheet.

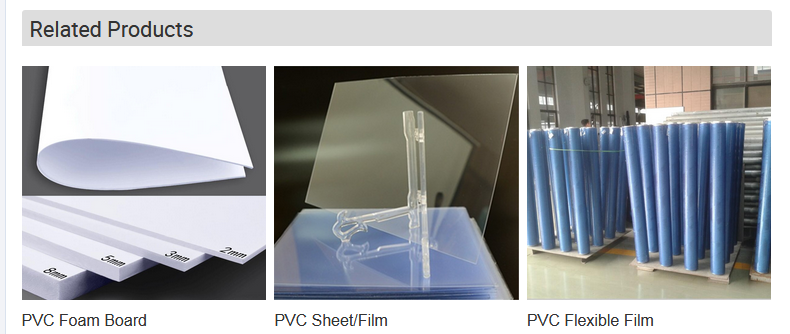

Rigid plastic sheet for tray forming special flexible plastic vsp film for tray sealing function.

Term used to describe forming into a female mold drape forming.

Is industry proven in the manufacturing of premium pvc rigid sheets for a wide variety of thin and thick gauge forming applications.

Thermoforming typically involves heating a sheet of plastic and stretching it over a mold.

Vacuum forming the walplax rigid vinyl product line includes numerous material formulations ideal for thermoforming and vacuum forming applications.

This selection of materials are best known for their excellent formability in addition to their individual traits of toughness chemical resistance and heat resistance for example.

Some of our most popular types of flexible plastic sheet include these.

Amorphous plastics like abs and polycarbonate generally have wide processing windows and good melt strength making them easy to thermoform.

Only 3 left in stock order soon.

When the plastic is heated it can easily stretch over any type of mold without tearing or breaking.

Dental lab 20pcs hard vacuum forming plastic sheets thermoforming plastic sheet splint material 1 0mm.

As it cools however it hardens and solidifies permanently retaining the new shape.

Specialty acrylic sheet offers the ability to add even more benefits like uv blocking glare free finishes bulletproof strength abrasion resistant coatings and more.

Vsp vacuum skin packaging the thermoforming packaging machine is noted for its features of multi function and convenience in the packaging of food and non food products.

Basic vacuum forming process.

4 2 out of 5 stars 15.

Overview of thermoforming thermoformable plastic sheets from professional plastics.

The benefits of acrylic make it well suited for a wide range of applications.

Term used to describe forming over a male mold webbing.