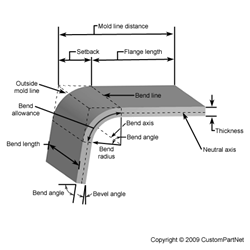

Bend radii and minimum bends are limited to certain values or ranges which are determined by the equipment and tooling combinations available to the manufacturer.

Minimum bend radius mild steel sheet.

The minimum inside bend radius is even larger when bending with the grain.

To keep it simple i also use a 2 mm inside radius.

The minimum bend radius data shown in these charts is measured to the inside of the bend.

Thick grade 350 and 400 may have a minimum bend radius of 2 5 times the material thickness when transverse bending while longitudinal bending may require a minimum bend radius that s 3 75 times the material thickness.

So in this case the minimum inside bend radius is 2 times the material thickness.

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.

Now multiply that answer by the plate thickness.

Bend radii minimum bend sizes.

Divide 50 by the material s tensile reduction percentage as specified by your supplier.

4 0 5 2.

Again the minimum inside bend radius is even larger when bending with the grain.

Note that this is just a rule of thumb.

The lowest common bench capacity is around 100 tonnes.

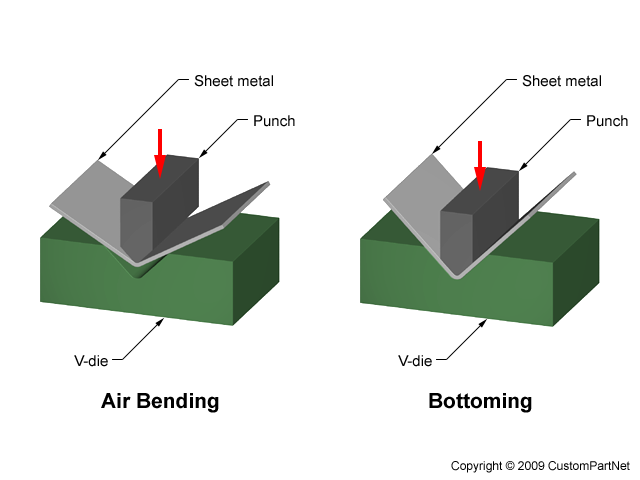

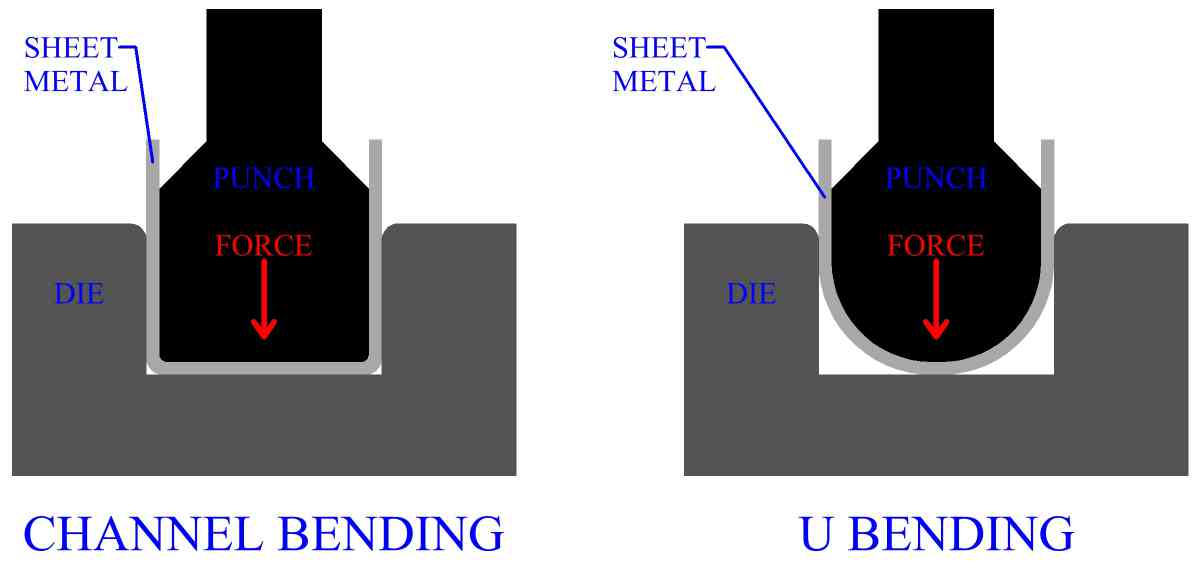

The gauge inside radius die opening and minimum flange length are all interconnected through different equations and relationships the air bend force.

I can now see that the minimum flange length is 8 5 mm for such a bend so i have to keep it in mind when designing.

Use this document to choose values that are both manufacturable and meet your needs.

In steel between 0 5 and 0 8 in.

This tool allows you to determine tonnage internal radius v die opening and minimum flange you just have to insert the characteristics of the sheet metal to be bent.

This value will vary by grade.

Thick grade 350 and 400 may have a minimum bend radius of 2 5 times the material thickness when transverse bending while longitudinal bending may require a minimum bend radius that s 3 75 times the material thickness see figure 1.

Discover all our calculation tools in the calculators section of the top menu.

Steve benson the president of asma llc shares a handy rule of thumb for determining the minimum bend radius for steel forms.

If the material is 0 5 in.

When designing sheet metal parts and enclosures it is helpful to use these values as the basis for your design.

Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal.

Finding the true minimum bend radius for steel or aluminum plate requires a little research.

Determining the minimum internal radius for a bend in sheet metal.

Being able to read a bend force chart is crucial for any brake press operator and sheet metal engineer.

Let s say i have a 2 mm thick sheet and i want to bend it.

It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii.

The required die width is 12 mm and tonnage per meter is 22.

In steel between 0 5 and 0 8 in.