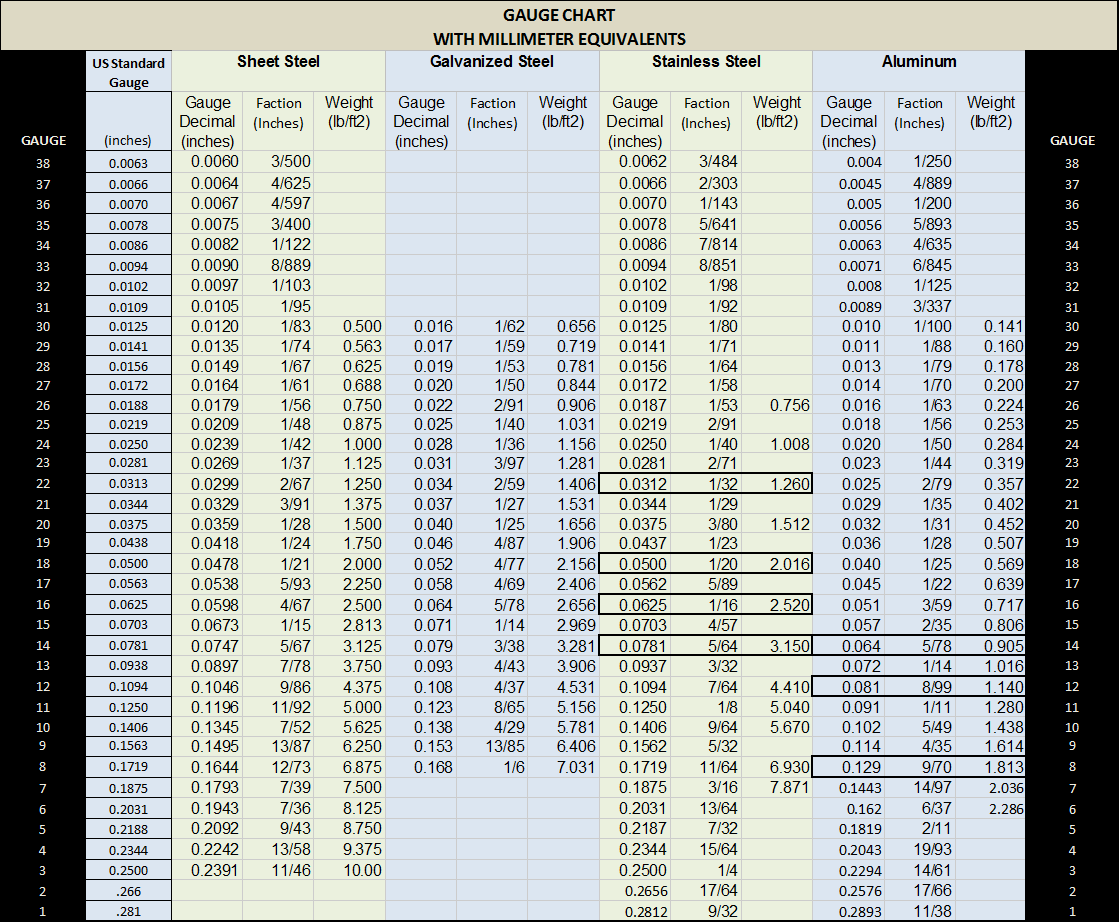

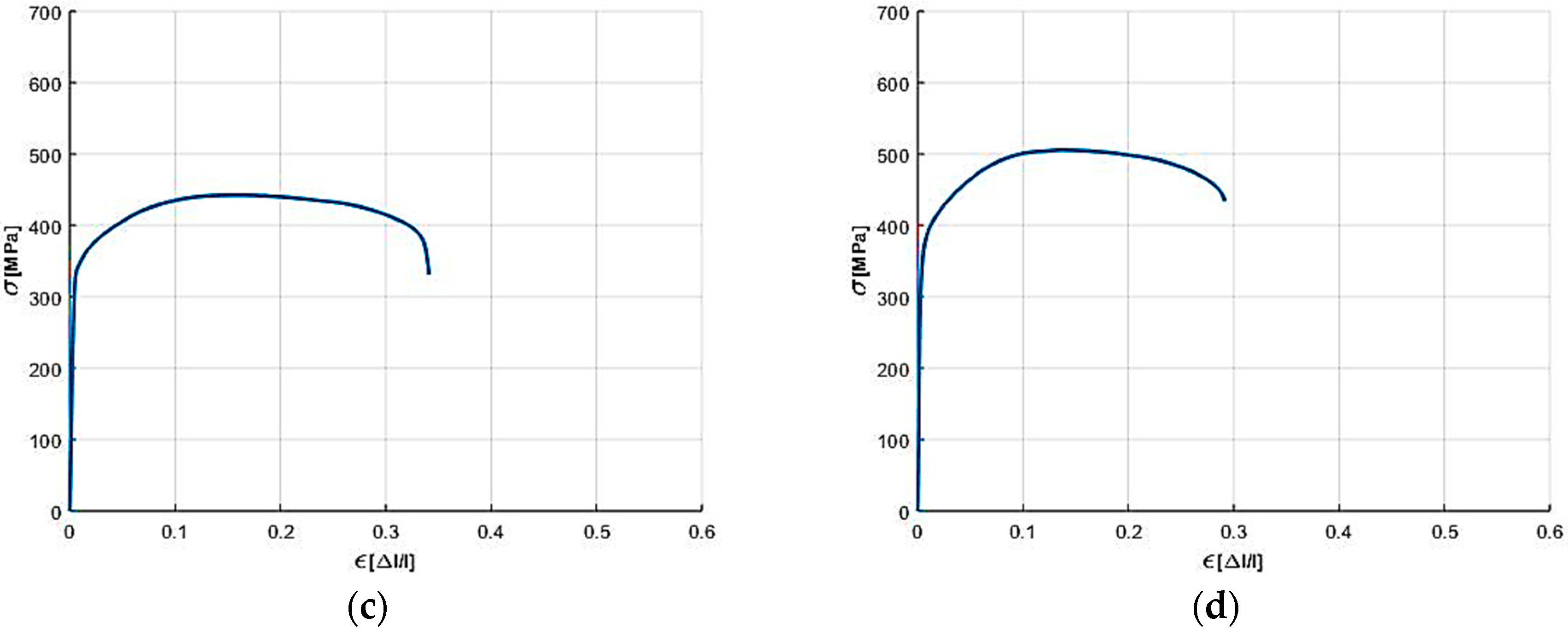

The tool can calculate the required bending force for bending aluminum stainless steel mild steel and weldox or strenx high strength steels.

Minimum bend radius 304 stainless steel sheet.

It is possible to choose other bends if you require but additional lead time and tooling charges may apply.

Material bend radii and minimum bend size charts please note.

18 8 type 302 020 063 063 063 063 063 063 063 063 063 025 094 063 063 031.

For instance right now in solidworks for say 11 ga sheet metal i use a bend radii of 0 005 and a k factor of 0 275 and that seems to work pretty well when i put the flat views on my prints.

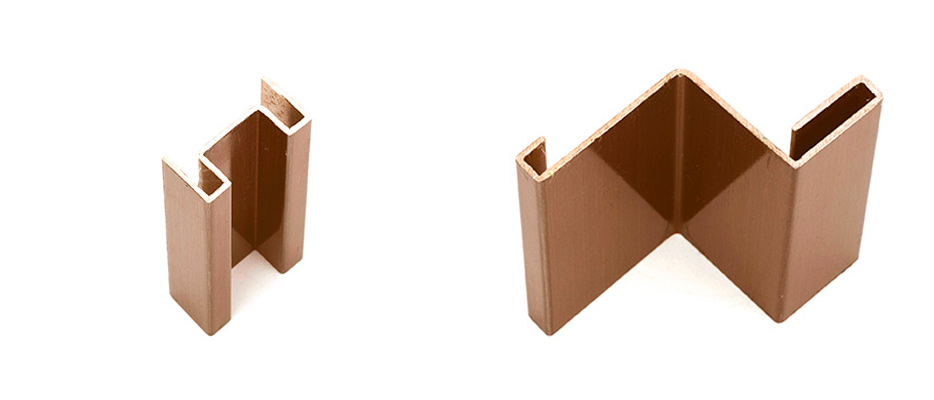

To get the best results a design engineer has to account for many factors such as the end use of the metal form the material the sheet metal is made of plain steel stainless steel etc and the dimensions shape of the final product.

Making a custom metal form using sheet metal is a surprisingly delicate process.

You described a rough rule to find a steel s minimum bend radius.

Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal.

So i am looking for the parameters for 304 ss that will have the same outcome.

For thin gauges 063 and less 1 2 the material thickness for simple bends of 90 degrees or less is acceptable.

The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius.

For hems a bend of 180 degrees it s highly desirable to use at least one material thickness for most alloys in this size range and essential for aluminum.

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase.

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

And by that i mean the cut out prior to bending comes out to the right size.

Discover all our calculation tools in the calculators section of the top menu.

Aluminum is less forgiving than cold rolled steel or stainless steel.

Divide 50 by the material s reduction percentage as specified by the material supplier subtract by 1 and then multiply by the plate thickness.

This tool allows you to determine tonnage internal radius v die opening and minimum flange you just have to insert the characteristics of the sheet metal to be bent.

Sheet metal bend radii if these guidelines are not followed more research and or some form of analysis may be requried.

Recommended minimum bend radii for steel and aluminum.

We go beyond the general rules of sheet metal bending as our customers want tight bend radii for sheet metal parts.