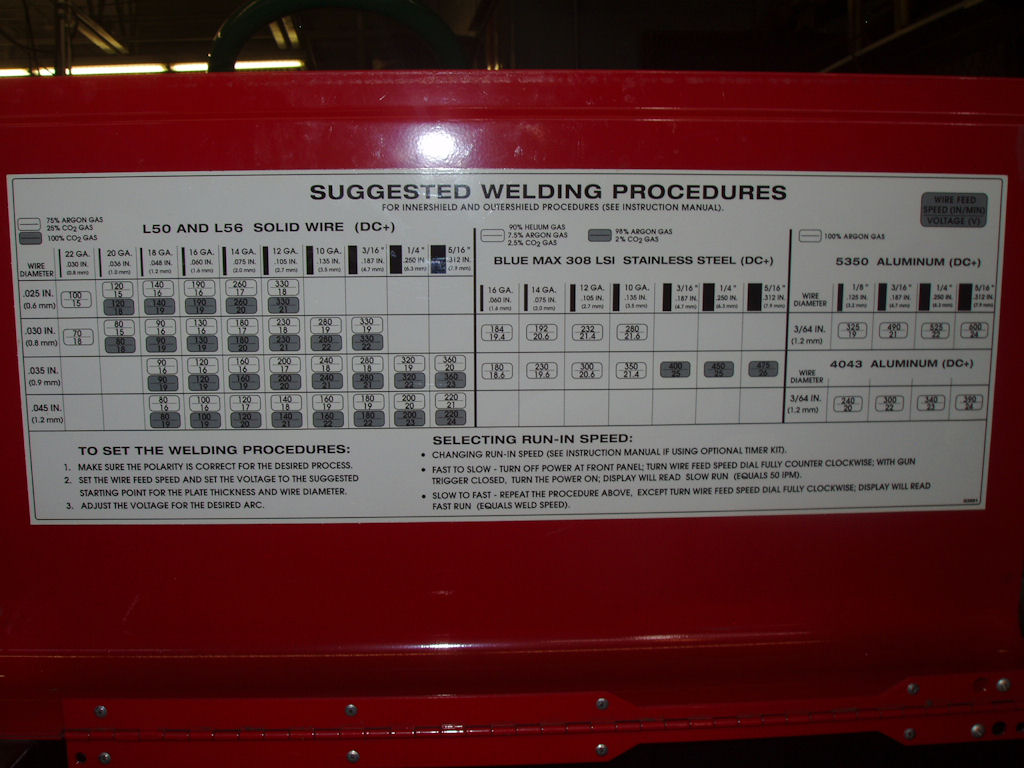

Mig welder settings for various metal thickness s mig welder settings can vary substantially from model to model and certainly from brand to brand.

Miller or lincoln mig for thin sheet metal.

Holding the tip too far from the surface will cause the wire to have to come out too far to touch the metal.

It s one of the highest quality machines available and comes incredibly low priced.

Don t attempt to weld thin materials like sheet metal with flux cored wires which put more heat into the base metal.

Just a video for diy guys or girls thinking about getting into mig welding and how to set the machine up for sheet metal welding as far as sheet metal weldin.

For thinner gauge sheet metal like 18 or 20 gauge we suggest 023 6mm wire in your mig welder.

Lincoln electric powertec 191c mig welder millermatic 180 and portamig 185 your opinion is appreciated thanks.

Mig welding is the preferred method for most automotive bodywork and since sheet metal is the thinnest of metals a large expensive mig unit is usually not required.

Keep the stick out short stickout of your mig wire is important when welding any type of metal but especially sheet metal.

I keep blowing through my thin sheet.

To weld sheet metal with solid wires use electrode positive ep or reverse polarity.

Andy gives helpful insights and tips to mig weld thin sheet metal.

While sheet metal is primarily a tig welding job there are times when it s handy to have an available mig welder to fuse sheet metal.

Tig welding sheet metal.

Forget the larger 1 8 inch tungsten electrode and use a smaller one.

This article is more a general guideline to help the novice welder understand how the various settings will affect your results.